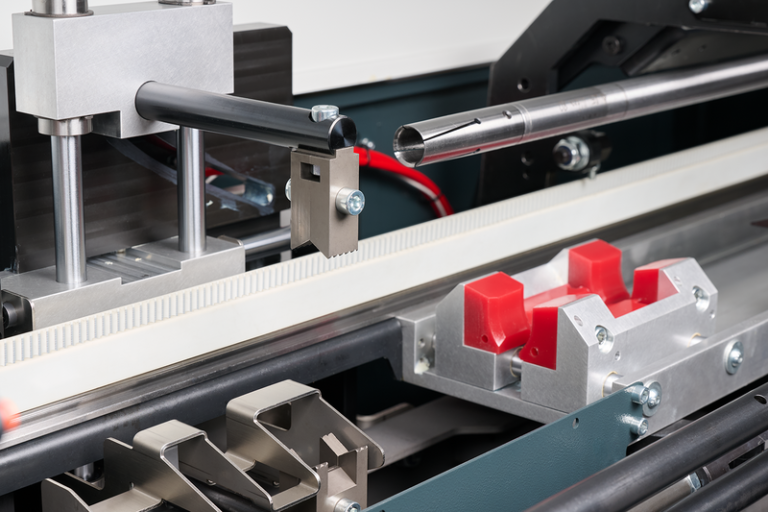

Automatic Front Support for All Bar Sizes and Shapes

With a sleek and well-thought-out design, the front support is positioned just behind the spindle entry, providing optimal bar guidance at every stage. Fully automatic adjustments and perfectly shaped elements ensure top performance—regardless of diameter or shape.

Modern, Easily Accessible Electrical Solution

The upgraded electrical cabinet with dual side doors offers easier access and maintenance, saving you both time and effort.

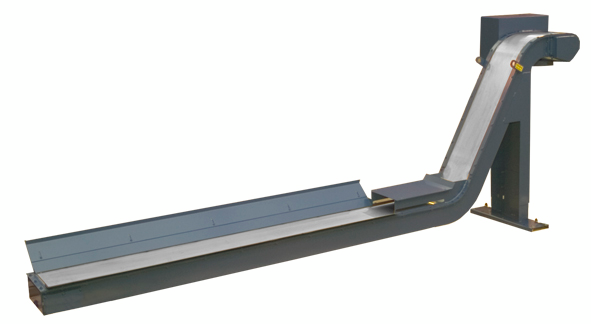

Maximized Stability with an Innovative Core Beam

The core beam—at the heart of every bar feeder—has been redesigned using cutting-edge technology to deliver industry-leading vibration dampening. The result? Greater precision, reduced wear, and enhanced machine longevity, even at high spindle speeds.

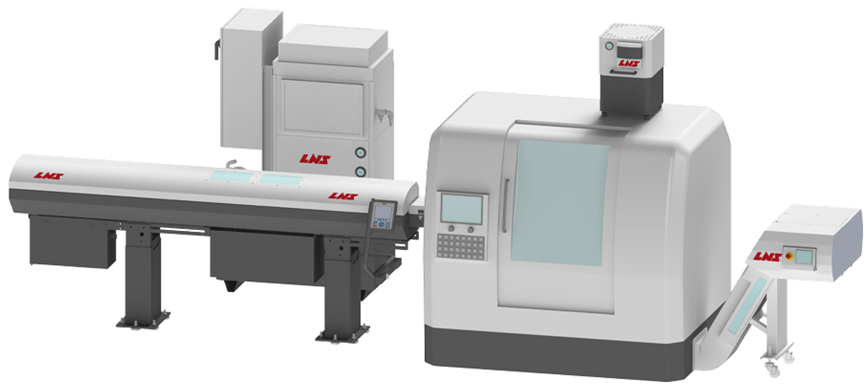

Automatic Diameter Adjustment – Seamless and Cost-Efficient

The EXPRESS 346 evo revolutionizes bar handling with its fully automatic adjustment system. Simply enter the bar diameter using the remote control, and the feeder automatically adjusts all mechanical components and channel diameter—without needing to swap out any channels.

Change the collet, and you're ready to go—quickly, easily, and without interruption.

Efficient Storage and Easy Access

Specially designed drawers keep accessories like collets and rotating bearings organized and within reach. The wide, ergonomic access ensures you always have the right tools at hand.

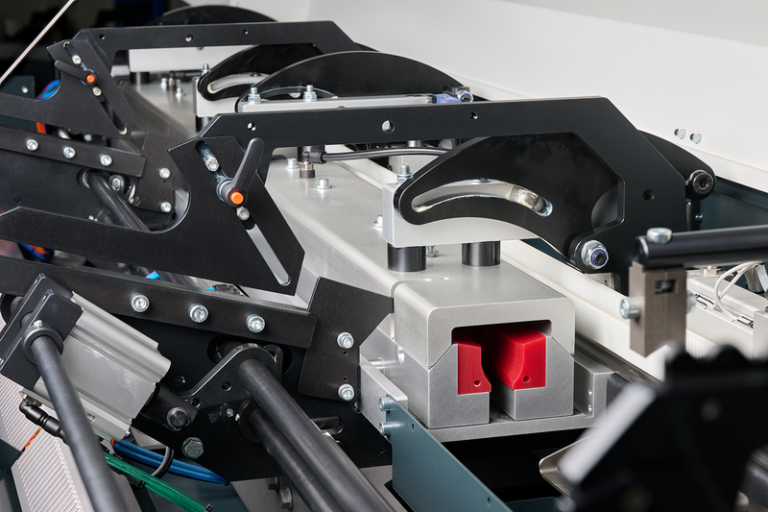

Automated Remainder Extraction System

The powerful, pneumatically controlled remnant handling system requires no manual adjustments. This intelligent solution saves time and keeps your production smooth and hassle-free.

High-Capacity Loading Ramp for Extended Production

The EXPRESS 346 evo features a 280 mm loading ramp capacity, making it ideal for long, unattended production runs across the entire diameter range (3–46 mm).

Invest in the Technology of Tomorrow –

The EXPRESS 346 evo delivers reliability, precision, and unbeatable performance for all your production needs.